> 산업분야 > CNC/Robot

> 산업분야 > CNC/Robot

CNC/Robot | Industry

Automotive industry

자동화시장에 직회된 HMI, PLC, Motor, Drive, PC, 감속기, 원격제어시스템, Power Supply, 단자대, 릴레이, 케이블등

"BA technology removes the boundaries between machine and robot. The robot becomes a mechatronic system component in the truest sense of the word."

Tomas Prchal, Global Technology Manager - Metal and Robotics

▣ Handling and robotics

B&R offers the most advanced form of integration – with robots incorporated seamlessly into the machine control logic. Whether it‘s a press brake, packaging line or injection molding system, the machinery and robots utilize the same processor, memory and timing. Robot and machine are fully synchronized with a jitter [1 μs. The common DC bus for machine and robot drives enables maximum energy efficiency.

Benefits for robot integration

⊙ Highest productivity due to robot-machine synchronization

⊙ Energy efficiency

⊙ Universal engineering tool for simulation, programming, testing and commissioning

⊙ Web-based diagnostics and remote maintenance

▣ Mobile panels

Mobile operator panels offer users maximum flexibility – allowing them to operate the machine right from the center of the action. B&R Mobile Panels are comfortable to hold – for both right and left-handers – and do not cause fatigue even after working for longer periods of time. mapp View opens up new dimensions in robot operation by providing access to HMI applications over modern communication platforms such as smartphones.

⊙ High-resolution displays

⊙ Intuitive touch-screen operation

⊙ Robust construction

⊙ Lightweight

⊙ Ergonomic layout for right or left-handed operators

▣ openROBOTICS – COMAU robots controlled by B&R mapp technology

With openROBOTICS, COMAU robots can now be completely and seamlessly integrated into machines and production lines equipped with B&R automation components. openROBOTICS allows a level of usability, performance and precision that would never be possible with cumbersome conventional interfaces between robot and machine control. The Comau openROBOTICS series is a complete family of robots with payloads ranging from 3 to 650 kg.

⊙ Robot as plug-and-play component within B&R Automation Studio

⊙ ser-tailored HMI

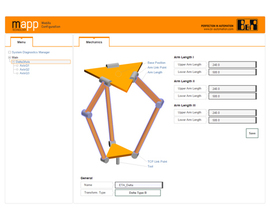

▣ mapp Technology

mapp technology provides an easy approach for integrating a robot with maximum functionality. This includes preconfigured axis adjustments and optimized path parameters, which can dramatically decrease the time needed for commissioning. Web-based faceplates make it possible to configure the robot and perform diagnostics using in a browser.

⊙ Easy robot integration with maximum functionality

⊙ Dramatic shortening of the startup time due to tested axes- and path- parameter settings

⊙ Use of web-based faceplates for robot configuration and diagnostic

▣ Communication with robot control via POWERLINK

Numerous robotics manufacturers have already integrated POWERLINK in their robot controllers, allowing robots to be incorporated into machine automation systems. For machine manufacturers, this advancement considerably simplifies the programming of robots.

Robot control via POWERLINK

⊙ IEC 61131-based robotics programming

⊙ Robot integrated into Automation Studio

⊙ Reduced hardware costs

⊙ Large selection of robotics platforms

▣ One solution for many kinematic systems

Regardless of the type of kinematics, number of axes or size of motors involved – B&R offers a uniform software solution fully abstracted from the hardware layer.

Robot control via POWERLINK

⊙ Control Cartesian, serial and parallel robots using mapp technology

⊙ Openness for user-defined kinematics

⊙ All types of axes: servo, stepper, hydraulic

▣ Drive system – ACOPOS P3

B&R’s ACOPOS P3 enables a new dimension of machine and operator safety. Functions like Safely Limited Torque (SLT) and Remanent Safe Position (RSP) are essential for the safe operation of robots. The ACOPOS P3 is available as a 1-, 2- or 3-axis system. Its extremely high power density saves valuable cabinet space (up to 69% reduction in footprint).

⊙ Small footprint for compact machine design

⊙ Position control loop starting from 50 μs

⊙ Suitable for SafeMOTION and SafeROBOTICS technology

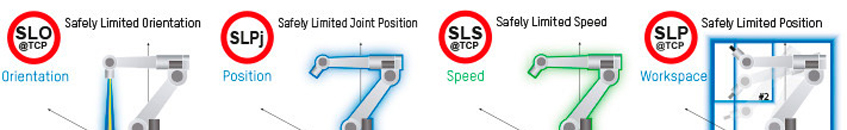

▣ Safety functions for robots

In order for humans and robots to work together safely, robotic movements must be monitored effectively and reliably. Only by integrating safe position and speed data from all axes involved in the kinematic chain can safety be ensured.

⊙ All serial kinematic chains

⊙ All serial kinematic chains

⊙ Shortest error reaction time, 7 ms on the axis level

⊙ Reduced machine footprint and volume